The TC290 temperature controller, based on the previous generation TC280 series, adopts various advanced technologies and is further upgraded and optimized. It has extremely high resolution, accuracy, and stability, and is at the forefront of the industry. It can support resistance sensors with diodes, thermocouples, platinum resistors, and negative temperature coefficients, and can connect up to ten temperature sensors to achieve the experimental purpose of multi-point testing. Simultaneously equipped with multiple communication methods such as Ethernet, RS-485, and USB, the data transmission distance is long, and data collection is convenient and flexible. The sensor adopts a balanced output dual constant current source method, which can automatically shift gears at extremely low temperatures, reducing the injection energy of the sensor and ensuring stable and reliable operation of the sensor.

TC290 has two control loops at the same time, and the input of each loop can be associated with any one of the ten sensors. It can be extended to two 100W or one 200W low-noise heaters at most, and can achieve closed-loop temperature control in multiple modes. It also has self-tuning function, making operation simpler and faster.

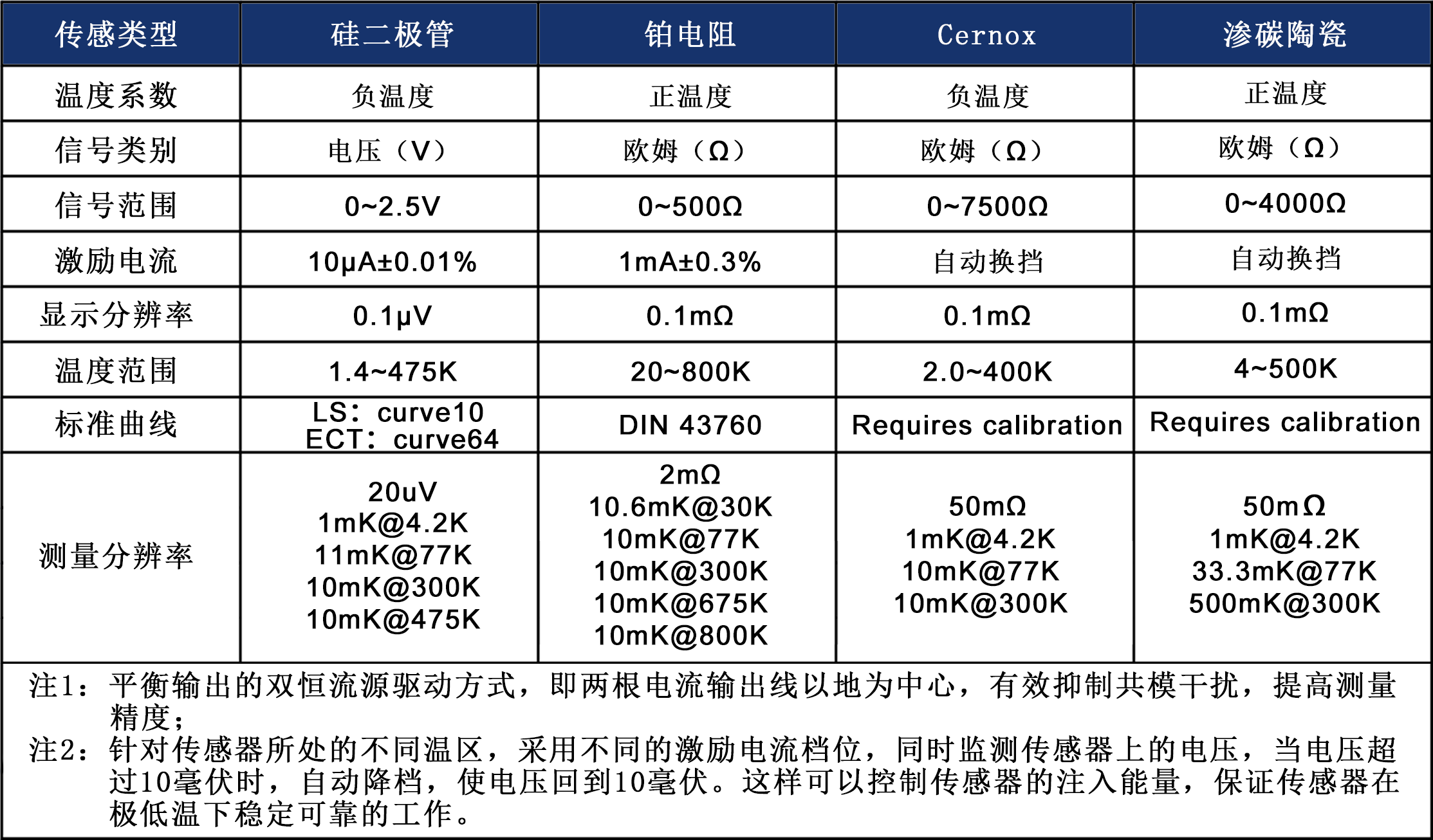

Measurement parameters

◆ Measurement accuracy: The optimal measurement accuracy can reach 10mK;

◆ Measurement range: Using an appropriate NTC RTD sensor, the measurement range can be as low as 300mK;

◆ Input channels: Two sensor input channels are standard and can be expanded up to 10, each with independent temperature curves;

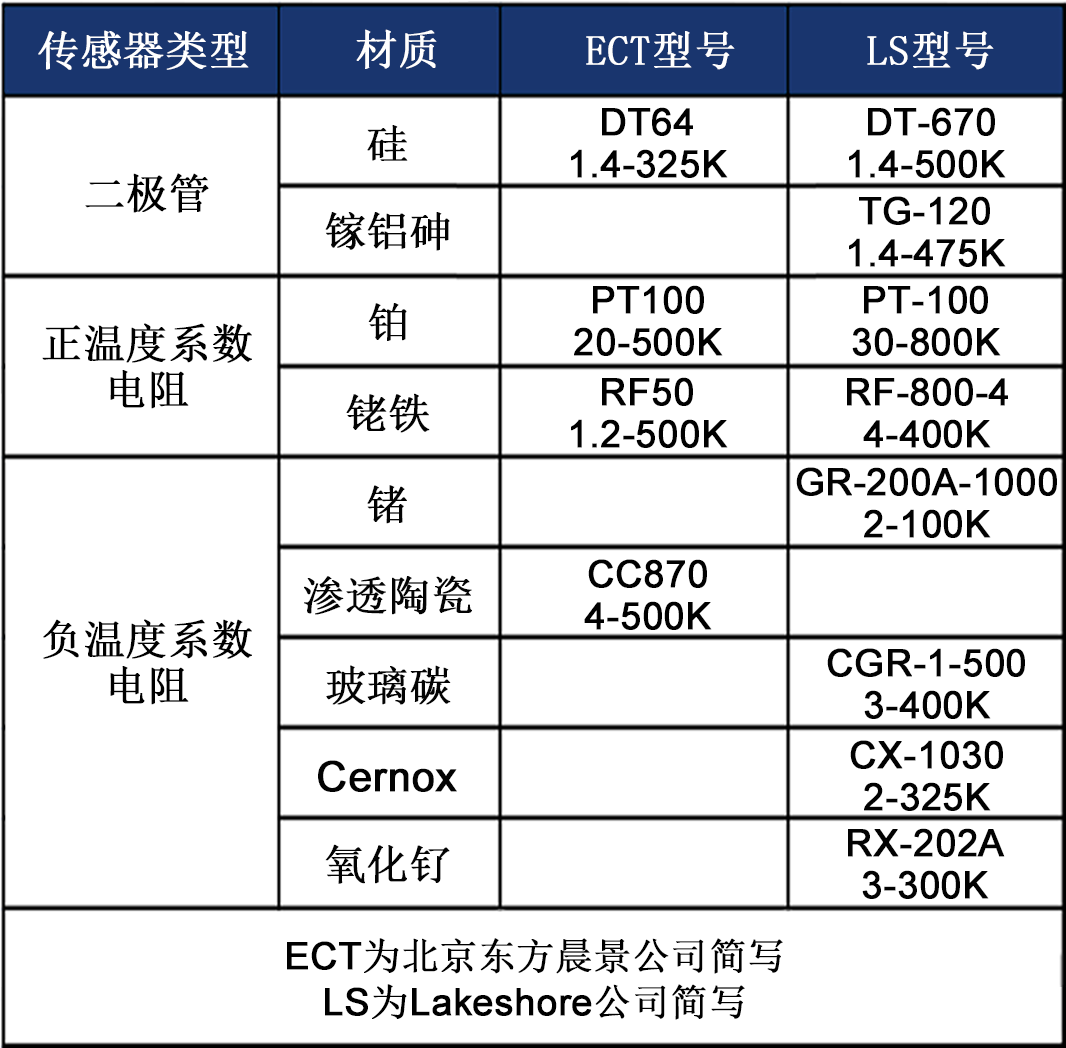

◆ Sensor compatibility: diode temperature sensors, Cernox temperature sensors, platinum resistance temperature sensors, thermocouple sensors, etc;

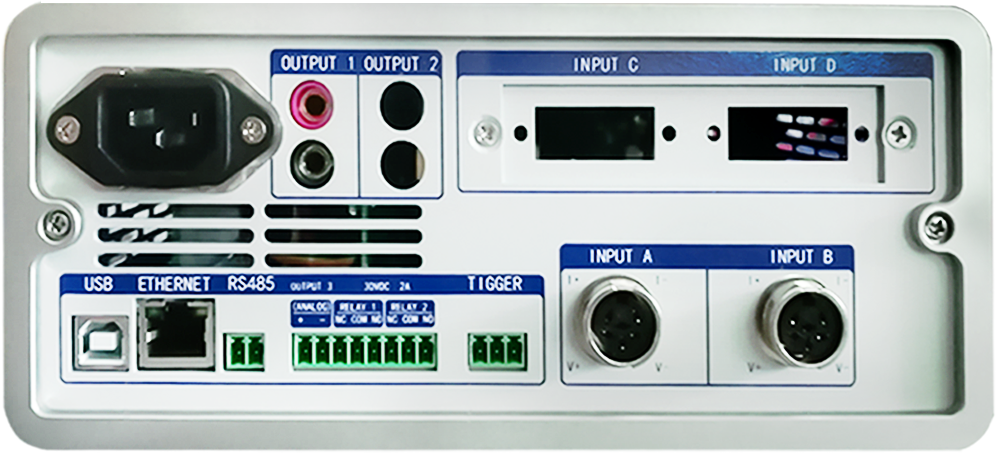

◆ Output control: Three independent heater outputs, supporting ± 10V analog voltage output, alarm, and relay control;

◆ Measure ADC: 24bit, update rate, 10 readings per second per channel;

◆ Thermoelectric potential compensation: supports the thermoelectric potential compensation function of resistance sensors;

◆ Networking operation: Multiple monitors can be networked for operation, and a single network allows up to 247 monitors to run simultaneously.

Control parameters

◆ Control loop: With dual control loops, the first loop is a low-noise heating power supply of 100W or upgraded to 200W, and the second loop is a low-noise heating power supply of 1W or upgraded to 100W;

◆ Signal filtering: Filter window 1-10% FS, filter points 2 to 64;

◆ Control methods: automatic adjustment, manual setting, and regional setting;

◆ PID control:

Set resolution from 0 to 1000,0.1 in proportion;

Set the resolution from 0 to 1000,0.1 for integration;

Differential resolution from 0 to 200,0.1;

Manually set the resolution from 0 to 100% and 0.01%;

◆ Regional function: can automatically switch sensor inputs for continuous measurement and control from 300mK to 1505K;

◆ Safety protection: temperature set point limit, curve temperature limit, heating output slope limit, heating power gear limit, heating off when powered on, heater short circuit protection.

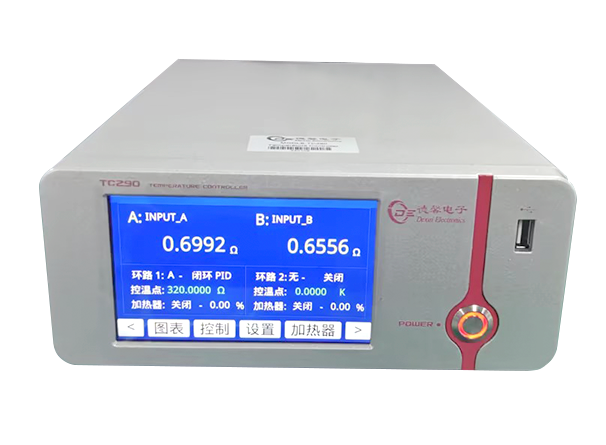

Human-computer interaction

◆ Display screen: 5 "color capacitive touch screen;

◆ Display mode: dual text in Chinese and English, with multiple temperature units of K, ℃, V, Ω;

◆ Temperature display resolution: 0.0001K

◆ Communication interface: standard Ethernet, RS-485, USB interface;

◆ Communication range: The transmission distance of the RS-485 interface can reach 1200 meters, and the distance of the Ethernet interface is basically unlimited.

◆ Communication protocol: Supports ECT custom protocol and standard MODBUS protocol.

◆ Software support: Provides LabView driver.

◆ Data storage: Allow storage of up to 64 temperature curves, including 20 curing standard temperature characteristic curves;

Sensor configuration

Sensor Input Performance Table